Business

MSJ provides safe, convenient living by being

faithful to the basics and promoting new technology development for the future.

Mold

Mold technology is

a key competency to determine the competitiveness of a product.

MSJ has established an overall mold development process ranging from plastic injection mold design to mold production and pilot injection. Mold industry is a Ppuri industry that serves as the foundation of quality and price competitiveness of manufacturing companies.

MSJ possesses technological power and expertise developed over the last 20 years for the design and

manufacture of precision gear mold for actuators and insert mold, a key electric vehicle battery part, as well as various automobile door module-related parts.

While assisting customers in securing development competitiveness by developing super engineering

plastic molds to replace the existing metallic products and supplying related parts and molds, MSJ has developed the technologies to manufacture a range of hot runner molds and back injection molds to ensure excellent exterior quality.

MSJ’s Mold Technologies

-

1 Technology to develop Super ENPLA mold to replace metallic parts

-

2 Precision injection molding gear and worm

-

3 Hot runner mold and back injection

-

4 Automobile door module parts

-

5 Electric vehicle battery parts

-

6 Insert injection

-

7 PPA/PPS/PEEK and others

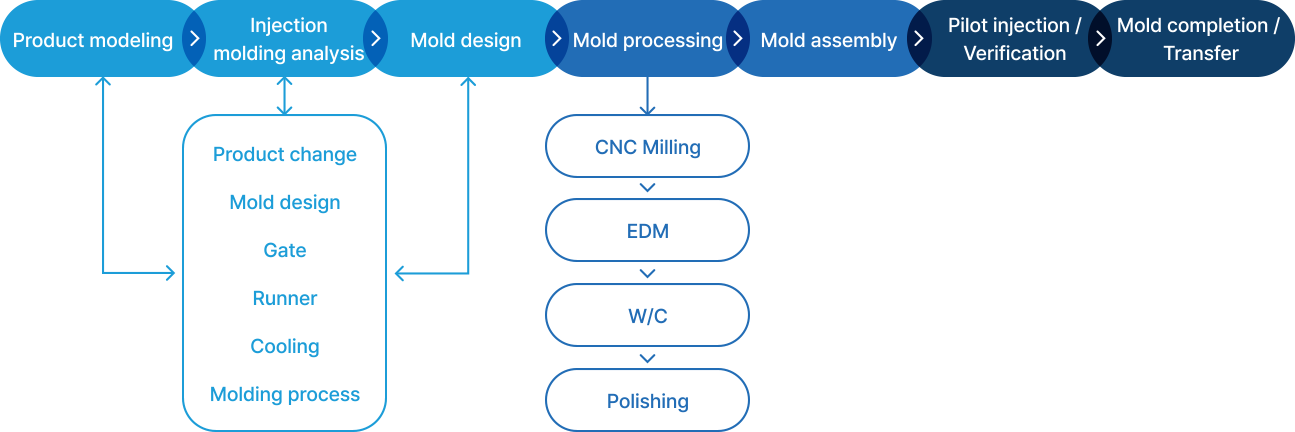

Mold Manufacturing Process

Mold Facilities

| No. | Facility | Maker | Capacity | Quantity |

|---|---|---|---|---|

| 1 | Wire cutting M/C | SODICK | 500 x 350 x 300 | 4 |

| 2 | CNC milling M/C | HWACHEON | 1,000 x 600 x 550 | 2 |

| 3 | Universal milling M/C | HWACHEON | 600 x 300 x 450 | 2 |

| 4 | Grinding M/C | JANGHAN | 500 x 200 x 300 | 5 |

| 5 | NC electrical discharge processing M/C | CHMER | 500 x 300 x 300 | 4 |

| 6 | Universal electrical discharge processing M/C | UNITECH | 350 x 200 x 200 | 5 |

| 7 | Lathe | HWACHEON | Φ 50 | 1 |

| Total | 23 | |||